ISC IBC Cu-Zebra Solar Modules

SC Konstanz’s N-type IBC Cu Zebra cells, utilizing Copprint copper inks for metallization, deliver 23% higher efficiency and require significantly less silver than previously projected for low-efficiency cells over the next decade.

In partnership with FuturaSun, ISC Konstanz is advancing single-junction c-Si technology toward mass production, featuring copper-screen printed bifacial TBC.

The Cu-screen printed bifacial polyZEBRA will revolutionise the PV industry, providing low-cost “double poly” devices with Voc values exceeding 735 mV and cell efficiencies surpassing 25%, driving both cost reductions and performance gains.

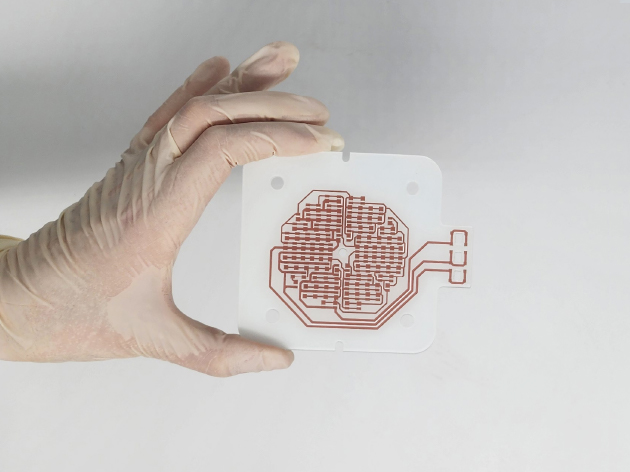

Amazing Cu screen printing bifacial ZEBRA (IBC)/polyZEBRA (TBC) ☀️☀️

– 120 M6 half cell bifacial IBC module

– advanced 3D printing layout

– Ag usage of <4mg/Wp (can go below 3)

– 80% fill factor

– 0.65 bifacial factor

>>> ready for production

The Evolution of Photovoltaic (PV) Technology

1. Pre-2018: Dominance of #AlBSF

Before 2018, aluminum back-surface field (Al-BSF) technology, using mainly mc-Si (multi-crystalline silicon) wafers and cost-effective aluminum alloys, was the industry standard. Efficiency was below 20% (Voc ~660mV), with improvements in bulk and rear-side recombination leading to progress.

2. 2018: Shift to Bifacial #PERC

In 2018, the rise of bifacial PERC (passivated emitter and rear cell) technology, enabled by low-cost Cz-Si from LONGi, PECVD AlOx, and advanced aluminum pastes, boosted average cell efficiency to 23.5% (Voc ~695mV), making it the “King of Energy Markets” from 2020.

3. 2023: Emergence of Bifacial #TOPCon

Bifacial TOPCon (tunnel oxide passivated contact) technology, integrating poly-Si(n) and LECO with high-purity silicon, now leads the market with an average efficiency of 24.5% (Voc ~735mV), becoming a key player in mainstream PV production.

4. 2028: The Future with Cu Screen-Printed #BC

Looking ahead, copper screen-printed back contact (BC) technology, paired with laser processing and efficient poly-Si(p), will drive cell efficiencies beyond 26% (Voc ~745mV). This will enable module efficiencies of 25-26% and a bifacial factor of 0.8, positioning PV to achieve an LCOE below 1¢/kWh by 2028.

The acronym PCB stands for printed circuit board, but PCBs aren’t actually "printed" — they’re chemically etched. So why do...

Congratulations to ISRA Cards for announcing their first temperature and humidity "made in France" RFID sensors based on copper inks.

Copprint has been nominated by the Cleantech 100 as a leading changemaker in the Materials & Chemicals category.